Welding Studs

AWS D1.1/D1.1M : 2006

AWS D1.1/D1.1M : 2006

Arc Stud Welding

Arc stud welding is generally used to weld large diameter fasteners to rougher and thicker base metals. Arc studs may be almost any shape and there are literally hundreds, however, they must have one end of the fastener designed for Arc welding.

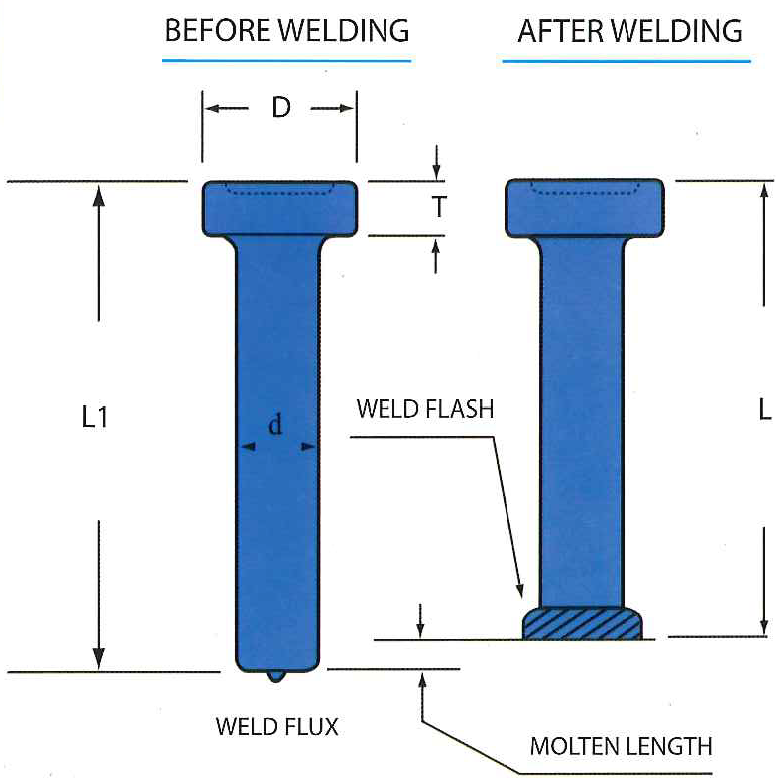

D=Diameter, L1=Length before weld, L=After weld

- A fastener and ceramic ferrule are firmly placed against the work surface under spring tension.

- Upon triggering, the weld gun automatically lifts the fastener from the base metal and initiates a controlled electric arc which melts the end of the fatener and a portion of the base metal.

- A ceramic arc shield concentrates the heat and retains the molten material in the weld area for maximum weld strength and reliability.

- At the precise moment the fastener and the parent metal become molten, the fastener is automatically plunged into the work surface. The metal solidifies and a high quality fusion weld is completed.

Size Range:

- DIA : M12 – M30

- LENGTH : 30 – 200mm

Finishing:

- Black (original)

- Mechanical Zinc Galvanized

- Dacrotized